400 million people globally need a prosthesis, but over 85% do not have access to one. Hence, there is potential for businesses to develop good quality but affordable solutions in this segment

According to the WHO, 0.5% of humans need a prosthesis, or 400 million people globally, and only 5 to 15% of amputees in any given population have access to a prosthesis, i.e. an artificial limb. Regions with the most trauma-related amputations are East Asia and South Asia, followed by Western Europe, North Africa, and the Middle East, then high-income North America and Eastern Europe. In Africa alone, estimates bring the number of amputees around 6.5 millions, and prostheses are a luxury for most of them.

While the demand is already considerably higher than the offer, the amputee population is expected to double by 2050, doubling an already underserved market.

As per the World Health Organisation (WHO), only 1 in 10 persons located in low-resource areas has access to adequate prosthetic technology, due to barriers of pricing and infrastructure availability.

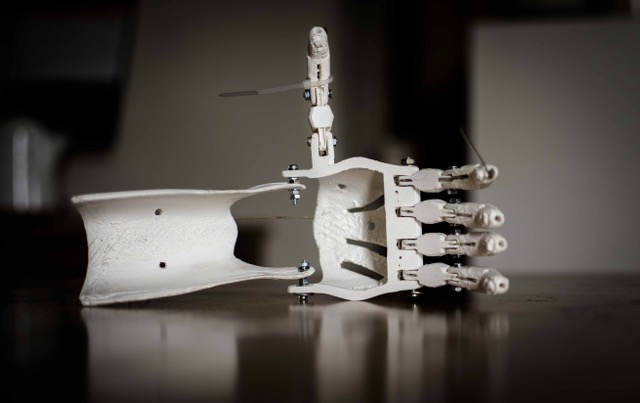

Given the size and expected growth of the market, there are potentially many opportunities to set up businesses and create value that benefits society. Given the high number of amputees not being able to afford regular prostheses that fit them, there is a need for affordable yet comfortable and practical prosthesis. 3D printing has demonstrated its capacity to produce such devices and cater to underserved populations, in remote and low-infrastructure areas.

3D printing of limbs solves the problem of cost, quality & access to infrastructure

- By being cheaper than regular prostheses

- By ensuring a correct fit of the limbs

- By reducing the infrastructure barrier

There are multiple examples through which 3D printing in prosthetics is helping overcome the price barrier.

- Ukuhamba Prosthetics, a South African company, uses recycled plastics to manufacture its artificial limbs, thus reducing the costs of materials.

- Startup 3D LifePrints out of Kenya was able to produce prostheses for $50 that competed with $2,000 traditional ones.

- In 2022, Netherlands-based non-profit 3D Sierra Leone, nominated for WHO’s Special Prize on Health Innovation, produced its models for $30.

- “Bionic” prostheses, which the user can move as they would a limb thanks to electrodes decoding myoelectric signals, are still pricier, but can be made for a hundredth of the usual retail cost.

3D printing is also reinforcing access, as poorly-fitted traditional limbs often discourage amputees to use a prosthesis. Since the printer adjusts to the data file it is given, the original file only needs to be altered with the results of the patient’s scanner to create custom-tailored prosthesis adapted to the users’ residual limb and the specific tasks they perform in daily life. It also allows for a more user-centric approach, fostering more emotional engagement, which is speculated to develop more ownership of the limb, particularly for children.

3D-printed prostheses help solve accessibility for people in remote areas or those without access to medical infrastructures. Instead of creating a mold and coming back 4 or 5 times to adjust it, then baking it and adding the resin, a simple compact scanner can be used. This little device replaces heavy equipment in a dedicated center and the method also requires less professionals. Scanner results are sent to a modelization software and printed. A professional then assesses the fit and gives instruction via video call, removing the barrier of a remote or underserved area. An important challenge, as per the World Health Organisation (WHO), only 1 in 10 persons located in low-resource areas has access to adequate prosthetic technology.

While around half of the 3D prosthesis makers are charities, 4 archetypes of business models exist among current players in 3D printing for prosthetic limbs

Half of the 3D prostheses players are charities, while the other half is made of (often small – 10-70 employees) businesses. It is worth noting that while NGOs are present globally, businesses are mostly represented in developed countries, although some examples can be found outside of them, like Instalib in the Philippines or Cure Bionics in Tunisia.

- Selling higher-end 3D prostheses as part of a larger medical products and prostheses offer, like Ottobock, a company with €1.3bn turnover in 2022, or multinational Össur

- Selling affordable 3D prostheses, often specialized on one limb (arms, legs…), like Open Bionics (founded 2014), Exoneo (founded 2017), or Unlimited Tomorrow (founded 2011). Companies in this segment are of small to intermediate size

- Selling softwares and education specifically to make prostheses, either as one-time purchase or subscription, like German company Mecuris

- Selling of softwares, materials and printers for prosthetics as part of a larger portfolio, like Ultimaker, Raise3D or EOS. These tend to be medium to large companies

To scale this further, we need firms and institutions encourage entrepreneurship

- The private sector to support universities to take products/research to the market

- The govt to support innovation and entrepreneurship through subsidies, funds, grants to reach BoP

While the technology exists, the 3D-printed prosthetic market for BoP is still largely untapped. To remedy this situation, both the private sector and governments have a role to play.

The private sector would be well-inspired to get more contact with universities and learn about their (often cheap due to restricted funding) innovations, which can open them the market of BoP populations. Point Design is a successful example, as it commercializes upper limb prosthetics developed by two Professors of the Biomechatronics Development Laboratory at the University of Colorado.

Public institutions also have their role to play to encourage the development of these businesses. Incentives have already proved their usefulness, as the example of Touch Bionics shows. Founded in 2005 and now part of Ossur, it is a spin-out of NHS Lothian and InnoScot Health, a public body to foster innovation in healthcare. It was sold in 2016 to Ossur, a listed global leader in orthopedics with 4,000 employees in 30 countries.

For example, a South African university student invented a 3D printed bionic prosthesis in 2014, which was awarded prizes in prestigious innovation competitions. The creator tried to turn Touch Hand into a company, was able to enter an accelerator and benefited from a free entrepreneurship training workshop and a grant to the university by the Technology Innovation Agency. However, despite these dispositives, which are not coordinated, almost 10 years later, the project remains within the university and relies on sponsors for its development and is still not offered to customers.,,,

Hence, innovation and technology are not the only necessary elements to boost the penetration of 3D printing in healthcare or other domains. Entrepreneurship training and support structures, subsidies or funds for businesses demonstrating their inclusivity are also needed.